I. Configure Board

Overview

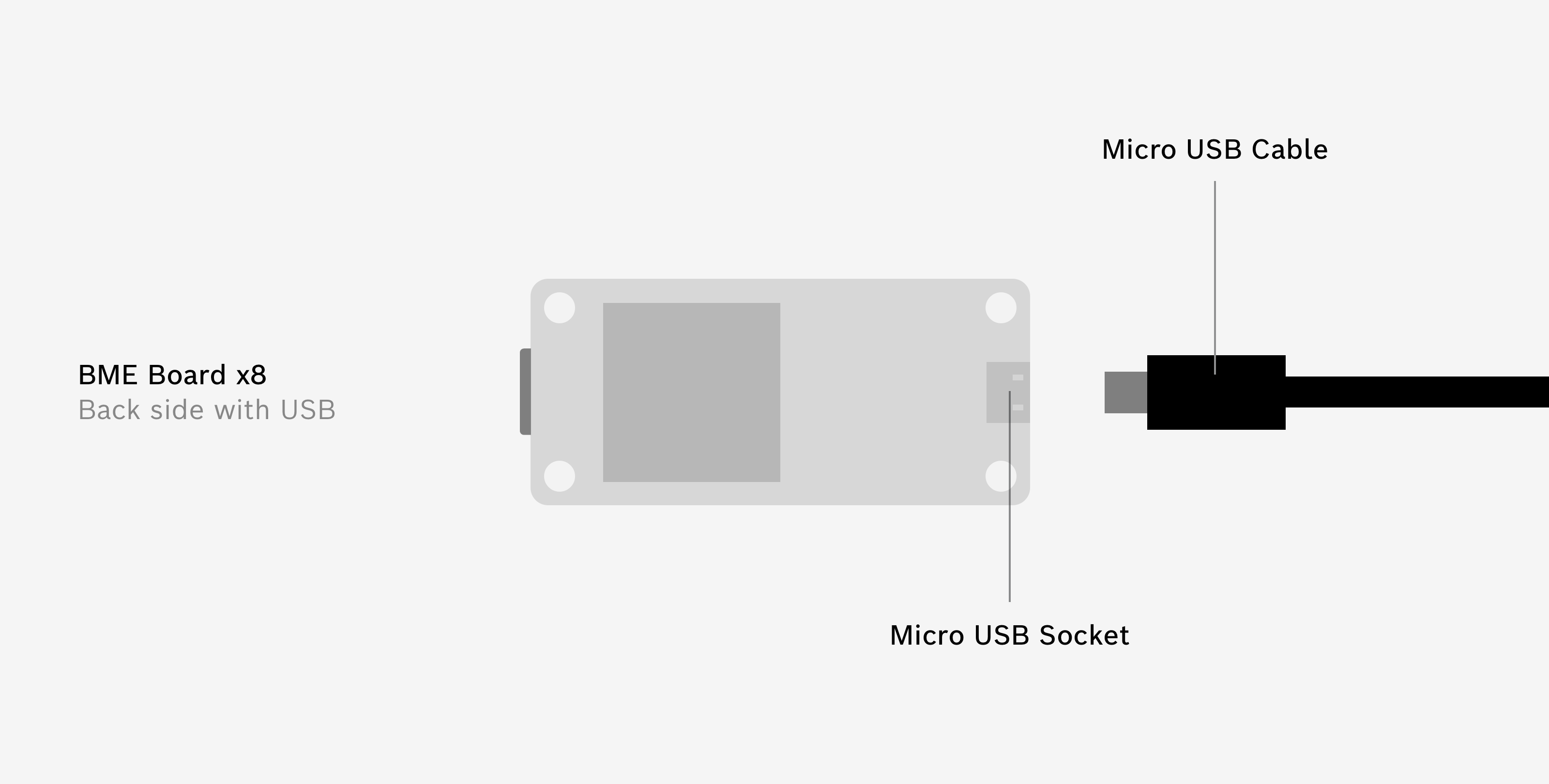

The first step in the process of using a BME Board with the BME AI-Studio is to configure the board. This step prepares the boards with a proper configuration for recording. The configuration is first defined within the application and then saved as a configuration file, that has to be transferred onto the SD card of the BME Board.

Create a configuration file

Open the application and create a new project by clicking Create new project on the Welcome screen. Alternatively, you can open the menu and select New project.... Next, a file dialogue opens. Please select, where you want to save your new project.

If you already have an existing project, just open the project and switch to your Specimen Collection.

To set up a configuration, click Configure Board. A new overlay opens that lets you define the configuration and save it as a configuration file to the SD card.

Three types of configurations

The operation with the boards is divided into three categories, which are intended for different phases with different goals:

Default configuration

The default configuration isHP-354andRDC-5-10and will suit most use cases. Select this configuration by using the board modeSensorboard Default HP/RDC. This mode can also be used for an initial stabilization which is needed before you can use them for data recording.Finding the right Heater Profiles

The power of adapting the BME688 gas sensor to a specific use case lies within the concept of Heater Profiles. Finding the right Heater Profile that suits best for your use case is key to getting peak performance results. Therefore we advise you to spend some time finding the optimal Heater Profile, which delivers the best results specifically for your use case. This involves sensitivity and selectivity. To explore a variety of Heater Profiles and find the best one for your use case, please use the board modeHeater Profile Exploration.Optimizing the Duty Cycle

The BME688 allows you to adopt its mode of operation in order to save energy. During a Sleeping Cycle the sensor is in low-power mode and will be automatically woken up after a certain amount of time to enter a Scanning Cycle. The ratio between how long the sensor is sleeping and scanning is defined by the Duty Cycle. To explore a variety of Duty Cycles and find the best one for your use case, please use the board modeDuty Cycle Exploration.

It is important to pay attention to individual combinations of Heater Profiles (HP) and Duty Cycles (RDC), so called HP/RDC combinations. Each sensor runs in a specific HP/RDC combination that determines the behavior how data is recorded. Not only is this important to the configuration of the boards and the recording of the data, but also for creating and training algorithms. One algorithm can use only identical HP/RDC combinations for training.

Board Type

Here you can choose the type of BME Board you want to create a configuration file for. In this version of BME AI-Studio, you can choose one board type:

- BME688 Development Kit with 8 BME688 sensors

Board Mode

The board mode can be set to different modes, depending on your goal.

Warning

Factory-new boards need to undergo a stabilization procedure. For stabilization you can use any board mode as long as you let it run for 24 hours.

Sensorboard Default HP/RDC is used to perform standard measurements. It uses the HP-354 heater profile, a versatile and short profile, which is best to begin with.

Heater Profile Exploration is used to scan a variety of Heater Profiles in order to find the one best suitable for a specific use case. In this mode you are able to choose multiple Heater Profiles, but only one Duty Cycle.

Duty Cycle Exploration is used if you want to optimize the Duty Cycling for a given Heater Profile. In this mode you are able to choose multiple Duty Cycles, but only one Heater Profile. Usually this mode is used for optimizing the energy efficiency, when you already found the best Heater Profile for your use case.

Heater Profile

In this section you can choose the Heater Profiles to be used in the Sensor Board configuration.

Select Heater Profiles

In order to make a selection of Heater Profiles, click on Select Heater Profiles ... and choose the desired Heater Profiles from the list. You can select multiple Heater Profiles, if you have chosen "Heater Profile Exploration" as Board Mode. You can select only one Heater Profile, if you have chosen "Duty Cycle Exploration" as Board Mode. Each Heater Profile can be viewed with its temperature sequence (graph and table) as well as a description of its purpose.

Different groups of Heater Profiles

The pre-defined Heater Profiles can be viewed as profiles that belong to different profile groups. This is also indicated by the numbering system within the name of the Heater Profiles. While exploring new use cases it is advisable to try Heater Profiles from various groups in the first place. Once it is clear which group of Heater Profiles work best you may explore this group in depth, by recording data with various Heater Profiles from this group and compare the results.

Maximum number of Heater Profiles

The maximum number of Heater Profiles (in Heater Profile Exploration) is given by the board type:

- BME688 Development Kit can be configured with a maximum of 4 Heater Profiles

Review Heater Profiles

Once you have selected your desired Heater Profiles, you will see them in the corresponding table. To quickly remove Heater Profiles from the list, you can click on X.

Please note

If you have chosen "Sensorboard Default HP/RDC" for Board Mode you can not choose any Heater Profile. The standard profile is selected automatically.

Duty Cycle

In this section you can choose the Duty Cycles to be used in the Sensor Board configuration.

Select Duty Cycles

In order to make a selection of Duty Cycles, click on Select Duty Cycles ... and choose the desired Duty Cycles from the list. You can select multiple Duty Cycles, if you have chosen "Duty Cycle Exploration" as Board Mode. You can select only one Duty Cycle, if you have chosen "Heater Profile Exploration" as Board Mode. Each Duty Cycle can be viewed with its specific number of Scanning Cycles and Sleeping Cycles and a schematic.

Additionally, you can see the percentage of Scanning Cycles within one iteration of a Duty Cycle. E.g. a 25% value means that for a quarter of the overall time the sensor is in scanning mode. This ratio also translates to the estimated energy consumption.

Maximum number of Duty Cycles

The maximum number of Duty Cycles (in Duty Cycle Exploration) is given by the board type:

- BME688 Development Kit can be configured with maximum 4 Duty Cycles

The table shows you the selected Duty Cycles. By clicking on X you can easily remove Duty Cycles from the list.

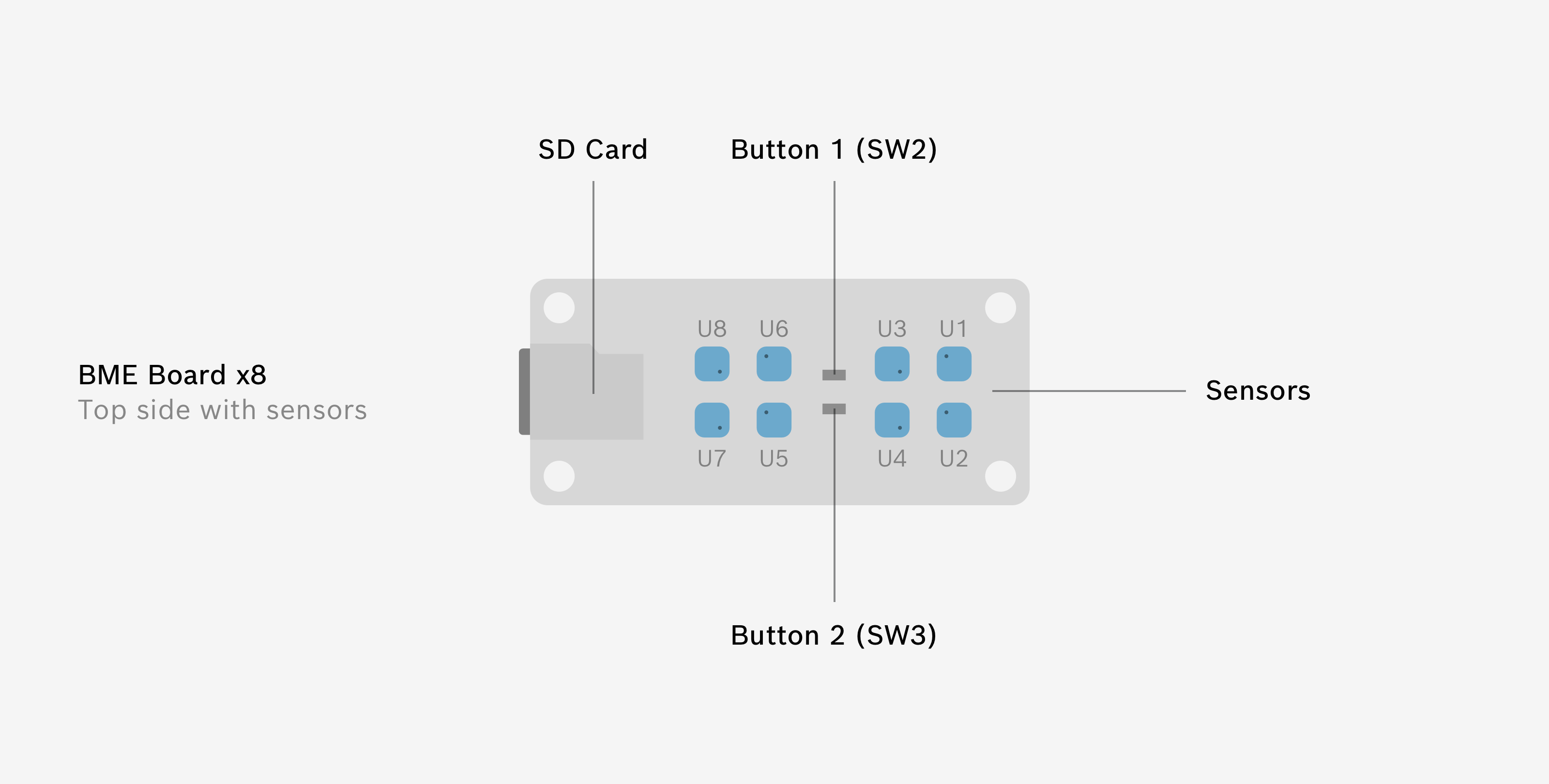

Board Layout

This option determines how the HP/RDC combinations are distributed over the available sensors on the BME Board. You can choose between three options:

Grouped places the combinations in a grouped way on the board. This can be thought of sequentially picking the sensors combination by combination and placing them on the board. It is the most obvious and easy to understand distribution.

Shuffled places the combinations in a shuffled or alternated way. This can be thought of sequentially picking sensors from each group and placing them on the board. This option gives a reproducible and evenly distribution. You may want to use this combination if you want to avoid grouping of sensors at certain positions on the BME Board. This may come in handy when you flush the BME Board with a focused stream of gas and you want to avoid the risk of having a systemic error in the gas concentrations per sensor configuration.

Random places the combinations in a randomized way. This can be thought of mixing sensors from each group and placing them on the board. This option gives an unintentional and evenly distribution. You may want to try selecting this option multiple times to get a new and independent randomization each time.

If the number of sensors on the BME Board is not divisible by the number of combinations, there will be residual sensors. These are filled up in an unbalanced manner, independent of the chosen board layout.

The actual distribution is shown in the corresponding schematic.